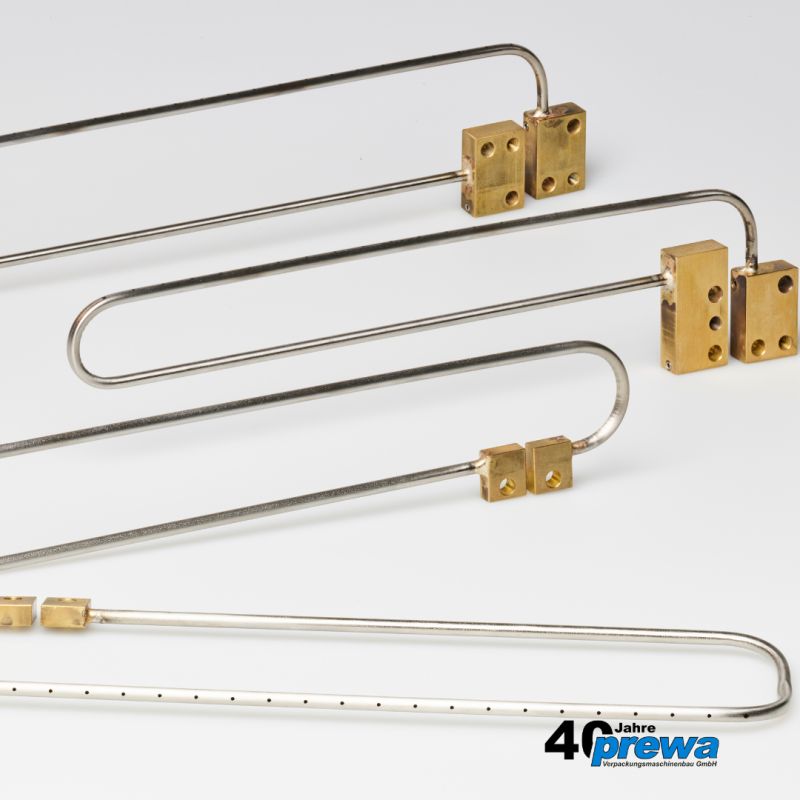

Impulse sealing band are heated in order to seal films. The sections of the band that are not in direct contact with the film or underlay can not emit heat and are therefore at risk to overheat. To avoid overheating in these critical sections and by that prolong the life span of the sealing band the electrical resistance is decreased by coating these sections.

The following types of coating are possible:

Silvering:

– Cheapest and reliable Method

– Thickness of the coating not controllable

Coppering:

– Most common method

– Thickness of coating is controllable

– Sectional coppering possible (Zebra bands)

Coppering plus nickeling:

– Layer of nickel prevents corrosion

– Used in application with hygienic requirements

Neuigkeiten

Spare parts for all hot air welders – direct from Prewa!

hether you need hot air tubes, hot air tubes or tubes for hot air – we have the right spare parts for your hot air